In the high-stakes world of UK meat processing, safety is more than a requirement—it’s a culture. From slippery kill floors to sharp butchers’ knives, every corner of the abattoir demands vigilance. That’s why investing in comprehensive abattoir PPE Manchester facilities trust is essential for protecting your team, maintaining hygiene, and ensuring operational efficiency.

This guide delivers a full-spectrum checklist of slaughterhouse equipment, protective gear, and best practices—designed for UK abattoirs that won’t compromise on safety or performance.

Hand Protection: Gloves That Guard Without Compromise

Cut-Resistant Gloves

Lacerations are the most common injury in meat processing. That’s why cut-resistant gloves UK processors rely on are a frontline defence.

Key features to look for:

- EN388-rated protection against cuts and abrasions

- Food-safe materials with anti-bacterial properties

- Dexterity for handling meat meat-cutting knife, butcher’s knife, and handsaw blades

Pro tip: Rotate gloves daily and inspect for wear—especially when working with giesser knives or Victorinox butchers’ knives, which demand precision.

Chain Gloves & Steel Gloves

For high-risk tasks like boning or hide removal, chain gloves UK and steel gloves offer unmatched protection.

- Stainless steel mesh construction

- Ambidextrous fit with adjustable wrist straps

- Ideal for use with dick knives, victorinox knives, and slaughterhouse equipment

Best practice: Use chain gloves on the non-dominant hand when wielding sharp tools to reduce injury risk without sacrificing control.

Footwear: Grip, Comfort, and Hygiene

Dunlop Purofort UK

Dunlop Purofort UK boots are a staple in meat processing for good reason.

- Lightweight polyurethane for fatigue-free wear

- Slip-resistant soles for wet kill floors

- Thermal insulation for chilled environments

Popular choice: Dunlop Purofort wellies with steel toe caps and chemical resistance—ideal for high-volume abattoirs.

Bekina Steplite UK

Bekina Steplite UK boots are engineered for comfort and durability.

- Resistant to fats, oils, and disinfectants

- Shock-absorbing heel for ergonomic support

- Reinforced toe and heel zones for added protection

Why it matters: In facilities using heavy-duty abattoir equipment, proper footwear reduces slips, trips, and musculoskeletal strain.

Body Protection: Aprons, Sleeves, and More

Body protection is often overlooked—but it’s critical in high-splash zones and during carcass breakdown.

Essential gear includes:

- Waterproof PVC aprons for fluid resistance

- Chainmail sleeves for forearm protection during hide removal

- Disposable overalls for hygiene-critical areas

Pair with: Cut-resistant gloves, chain gloves, and steel gloves for full upper-body protection.

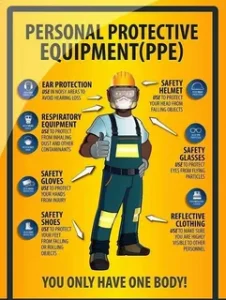

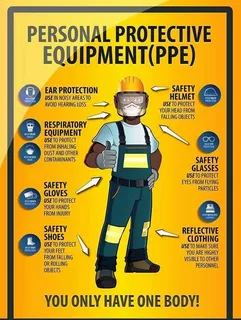

Head & Face Protection

Head and face protection is vital in areas with overhead hazards or high-pressure tools.

Recommended PPE:

- Hard hats with adjustable chin straps

- Mesh or polycarbonate face shields

- Ear defenders for noisy environments

Use case: Especially important when operating slaughterhouse equipment like saws, pneumatic tools, or dehiders.

Tool Safety: Blades, Sharpeners & Storage

Knife Safety Essentials

Every blade—from butchers’ knives to a meat-cutting knife—they must be sharp, sanitised, and safely stored.

Best practices:

- Use a steel knife sharpener throughout the day to maintain edge alignment

- Deep sharpen weekly with an oil stone

- Store victorinox knives, giesser knives, and dick knives in sanitised racks or magnetic strips

Handsaw Blades

- Replace handsaw blades regularly to avoid slippage

- Clean and sanitise between carcass types to prevent contamination

Tip: Keep spare blades on hand to avoid downtime during peak processing hours.

PPE Rotation & Maintenance

Even the best abattoir PPE Manchester has a lifespan. A structured rotation system ensures safety and compliance.

Checklist:

- Daily inspections for damage or wear

- Weekly sanitisation of chain gloves, steel gloves, and boots

- Monthly replacement of worn cut-resistant gloves UK, aprons, and face shields in the UK

Bonus: Log PPE usage and maintenance in a digital system to track compliance and reduce waste.

Training: The Final Layer of Protection

Even the best gear is only as effective as the people using it.

Training essentials:

- Blade handling workshops using Victorinox butchers knives, giesser knives, and dick knives

- Sharpening sessions with a steel knife sharpener and an oil stone

- PPE donning/doffing drills

- Safety refreshers on slaughterhouse equipment and hygiene protocols

Supplier tip: Brands like Victorinox and Kentmaster often offer on-site demos and training support.

Hygiene Protocols & Compliance

UK food safety standards demand rigorous hygiene practices.

Key protocols:

- Sanitise all butchers’ knives, handsaw blades, and meat cutting knife between carcass types

- Use colour-coded PPE to prevent cross-contamination

- Maintain sharpening stations with a steel knife sharpener and an oil stone

- Store PPE in ventilated, labelled lockers

Outcome: Better hygiene = longer blade life, fewer injuries, and higher meat quality.

Cold Room PPE: Staying Safe in Chilled Environments

Working in cold storage or chillers? Your PPE needs to adapt.

Cold room essentials:

- Thermal liners for cut-resistant gloves

- Insulated Dunlop Purofort wellies or Bekina Steplite boots

- Layered clothing under waterproof aprons

Why it matters: Cold-induced fatigue increases the risk of accidents—especially when handling sharp tools like giesser knives or Victorinox knives.

PPE for Chemical Handling & Sanitation

Sanitation teams face unique risks from disinfectants and cleaning agents.

Protective gear includes:

- Chemical-resistant gloves and aprons

- Splash-proof goggles and face shields

- Non-slip dunlop purofort boots with chemical resistance

Use case: Essential during end-of-day cleaning or when handling caustic agents near abattoir equipment.

Summary:

Equip, Train, Protect

From cut-resistant gloves in the UK to Dunlop Purofort wellies, every piece of PPE plays a crucial role in keeping your abattoir safe, compliant, and efficient. Combine the right gear with regular training and tool maintenance—like sharpening your butchers’ knives with a steel knife sharpener—and you’ll build a culture of safety that protects both your people and your product.

Whether you’re outfitting a new facility or upgrading your current abattoir equipment, this checklist ensures you’re covered—literally—from head to toe.